Electro Coagulation/Electro Floatation

Electrocoagulation technology, a promising water and wastewater treatment technology to treat complex wastewater streams. With this technology, metal cations are produced on the electrodes forming various hydroxides in the water depending on the water pH. Simultaneously pollutants can be removed from water by electroflotation, which occurs with electrocoagulation and further removal by filtration.

In recent decades, the application of electro coagulation systems has greatly expanded and are used for treatment of a variety of effluents containing metals, foodstuff, margarine, olive oil, textile dyes, fluorine, polymeric wastes, organic matter from landfill leachate, turbidity, chemical and mechanical polishing wastes (heavy metal removal), aqueous suspensions of ultrafine particles, nitrate, phenolic waste and arsenic.

Most highly toxic and non treatable industrial effluents with high COD, heavy metal , TSS and organic load can be easily treated effectively meeting discharge or reuse norms using electrochemical Coagulation and electro floatation methods, which is a emerging technology.

Inherent advantages of electro-chemical method is small foot print, minimal sludge generation , highly efficient, odour free , colour free treated water in single once through process with no chemical addition or dosing. Electro Coagulation removes ions, Fog, Silica, Organic Particulate matter and in addition it also reduce COD & BOD, TSS.

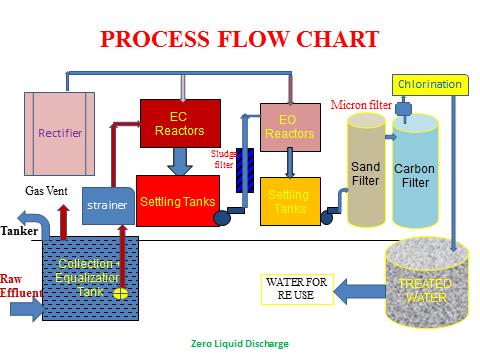

The Coagulation Electrolyzers used to treat the Industrial Effluents of Food Industry, Meat Industry, pharmaceutical industries, Textile plants, Dairy plants, etc. The attached Flow chart is self explanatory