The Platinised Titanium and Platinised niobium either platinum electrodeposited or metallurgical clad anodes are used as insoluble anodes in hard chromium plating bath, electrolyte such as… Chromic-Sulphuric acid and “HEEF-25" (high speed, etch-free).

For hard chrome plating, we design and manufacturing platinized titanium or niobium…

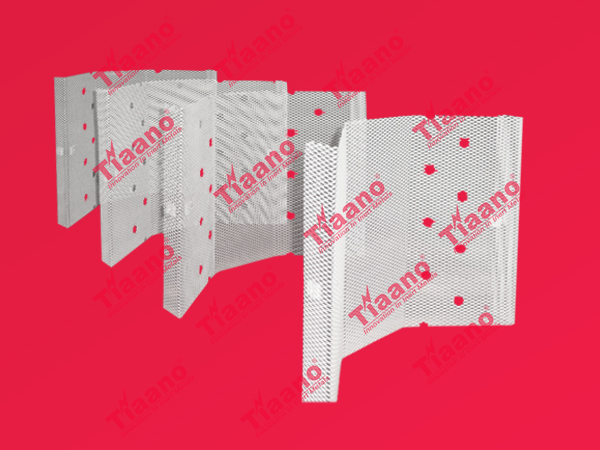

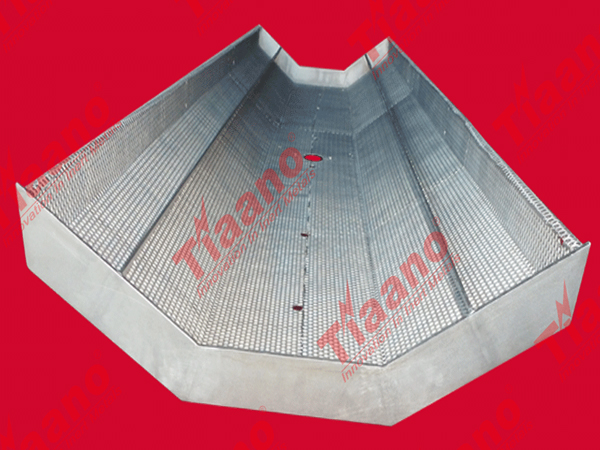

Ø Semi-rectangular anodes for rotogravure cylinders.

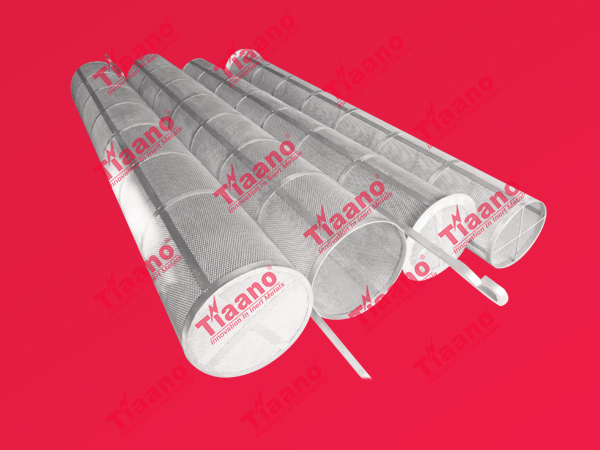

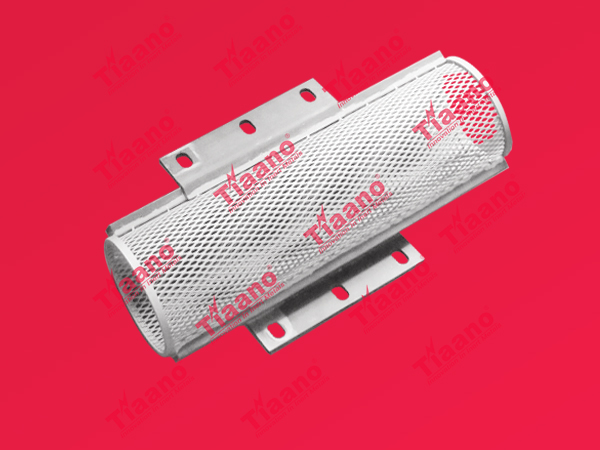

Ø Circular basket anodes for dynaChromshock absorber / piston rods chromium plating.

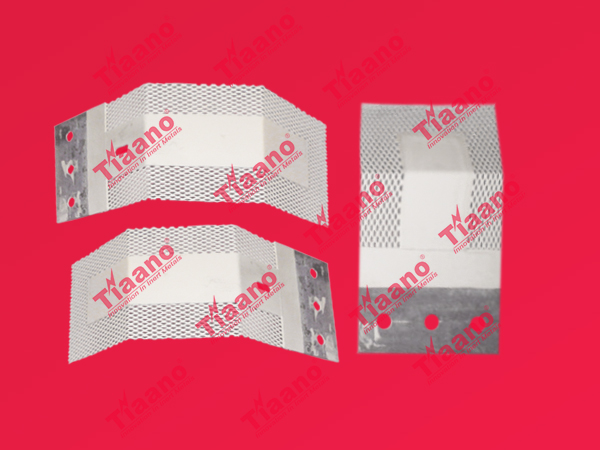

Ø Semi-circular anodes for piston rings.

Ø Custom made anodes for aerospace components.

Due to its excellent characters of… Dimensionally stable, Flexible in custom-made, Easy electrolyte flow, High electric throwing power, Low weight; most of our anodes are made from expanded metal substrate. Also our anodes are characterised by the features of…

v Design flexible according to the application.

v Complex shape custom-made fabrication.

v Easy maintenance and handling.

v Low electric resistance.

v Energy saving potential.

v Dimensionally stable and insoluble character.

v Excellent high life with high current density.

v Possibility of re-use by re-plating of platinum.

v Usage in fluoride containing baths.

v Excellent corrosion resistance characteristics.

v Higher quality of end product due to homogeneous deposition of chromium, Chrome plating is essentially faster and a chrome layer is very even (cause an even current distribution and enable the use of a higher current density - due to the constant electrolyte flow through anode mesh).

Other than expanded mesh, anodes can manufacture by substrates in the form of sheet, rod, wire, or pipe. The standard platinum layer thickness is 2 – 7.5 µm maximum up to 20 µm.

The lifetime of platinum plated titanium anodes is in particular dependent on the work medium (electrolyte) and the anodic current density. A longer service lifetime at even higher current densities (up to 10000 A/ M2) are achieved, when using in baths with low fluoride concentration. According to experience, the wear rate is approx. 1 to 4 grams of platinum per one million ampere hours in fluoride-free chromium baths.

Compared to platinum plated titanium anodes, platinized niobium anodes have a significantly higher breakdown voltage. In case of specific current densities of over 75 A/dm2 or upon the use of baths containing fluoride, we recommend the use of platinum plated niobium anodes.